Dispal

Advanced powder metallurgical AlSi alloys with low CTE and high stiffness.

Gränges Powder Metallurgy additive@granges.com Address Granges Powder Metallurgy SAS St Avold Nord ESPA Europort 57500 Saint Avold France |

HongKong Ying Jiang limited. ROOM 232,2/F SECURE HOUSE 68 HOW MING STREET KWUN TONG KL, HONGKONG +00852-28150191 mackli@yingjiang-hk.com Shanghai Jianghe Technology Co., Ltd. Room 302,Building 7, No.168 Jixin road, Minhang district of Shanghai +86 21 5488 2601 mackli@yingjiang-hk.com |

颖疆(香港)科技有限公司 香港观塘街何明街68号安全屋2楼232室 +00852-28150191 mackli@yingjiang-hk.com 上海疆禾科技有限公司 上海市闵行区集心路168号7号楼302室 +86 21 5488 2601 mackli@yingjiang-hk.com |

Very good form stability and high stiffness

The powder metallurgical process makes the alloys solidify extremely quickly. This results in the material having an extremely fine grain and homogeneous microstructure.

The DISPAL® material offers a higher specific stiffness than titanium alloys and steels. This combined with a high thermal conductivity and low thermal expansion gives it an exceptional form stability.

DISPAL® has properties comparable to those of steel but at only a third of its weight. It has a thermal expansion rate comparable with steel and a resistance to wear on the same level as cast iron alloys.

Sustainable high-performance aluminium materials

Aluminium is often referred to as the “green” metal thanks to its properties that support sustainable development. It is lightweight, strong, corrosion resistant, durable, versatile and impermeable – and also highly recyclable.

DISPAL® product range

DISPAL® is a range of hyper-eutectoid AISi alloys produced by powder metallurgy. They have a dimensional stability comparable with steel and a wear resistance on the same level as cast iron alloys.

| The DISPAL® alloys offers: | DISPAL® is available as: |

|

|

The DISPAL® portfolio

The spray-formed aluminium materials of the DISPAL® portfolio contains a high amount of Si (from 17% up to 35%). Our standard portfolio has six DISPAL® alloys that deliver outstanding results. For more detailed information on the materials, including data sheets, please click in the "Download” links.

|

DISPAL® |

Chemical composition |

Characteristics |

Download |

| S220 | AlSi35 | Low density | Download › |

| S221 | AlSi40 | Low thermal expansion | Download › |

| S225 | AlSi35NiFe2 | Lower thermal expansion at higher strength | Download › |

| S232 | AlSi20Fe4Cu3Mg | Strength, fatigue and wear resistance | Download › |

| S250 | AlSi20Fe5Ni2 | High temperature strength | Download › |

| S260 | AlSi25Cu4Mg | Wear resistant | Download › |

| S270 | AlSiFe4Ni3CuMgMnCrTi | Highest strength and stiffness at high temperature | Download › |

Customized alloys?

- Our innovative product developers have created numerous specialized alloys and the possibilities are endless. We are here to help you.

Product catalouge

Discover more about our Dispals products for lightweight precision parts.

Download Product catalougeAdditive manufacturing

3D printing, also known as additive manufacturing, is a method of creating a three dimensional object layer-by-layer using a computer created design.

DISPAL® S220, and DISPAL® S260, are qualified for Additive Manufacturing by Laser Powder Bed Fusion (LPBF) to create fully dense metal parts with short lead times.

- Printing of DISPAL® AM materials is done through a network of qualified partners.

- We support in the material engineering of your AM DISPAL® application.

- We provide lab services and powder material analysis based on your needs.

The process usually consist of a free initial assessment from a team of experts in GPM. We will collect all the necessary information to compile a case for you to draft the best action plan and connect you to the right partner depending on your geographical location and your product needs, being prototyping or serial production.

|

Printed DISPAL® |

Composition |

Download |

| AM S220 | AlSi35 | Download › |

| AM S260 | AlSi25Cu4Mg | Download › |

| Dispal® Design Guides | Download › |

A remarkable combination of properties and benefits…

+ ...high tensile strength (Rp0.2 up to 400 MPa)

+ ...high stiffness (Young’s modulus up to 100 GPa)

+ ...low weight (density from 2.54 g/cm3)

+ ...high temperature strength at working temperature up to 300°C

+ ...high fatigue strength of 250 MPa at RT (rotating fatigue 5x107)

+ ...good wear resistance (Hard Coat not necessary)

+ ... low coefficient of thermal expansion (down to 14x10-6/K

+ ...good thermal conductivity up to 150 W/m/K

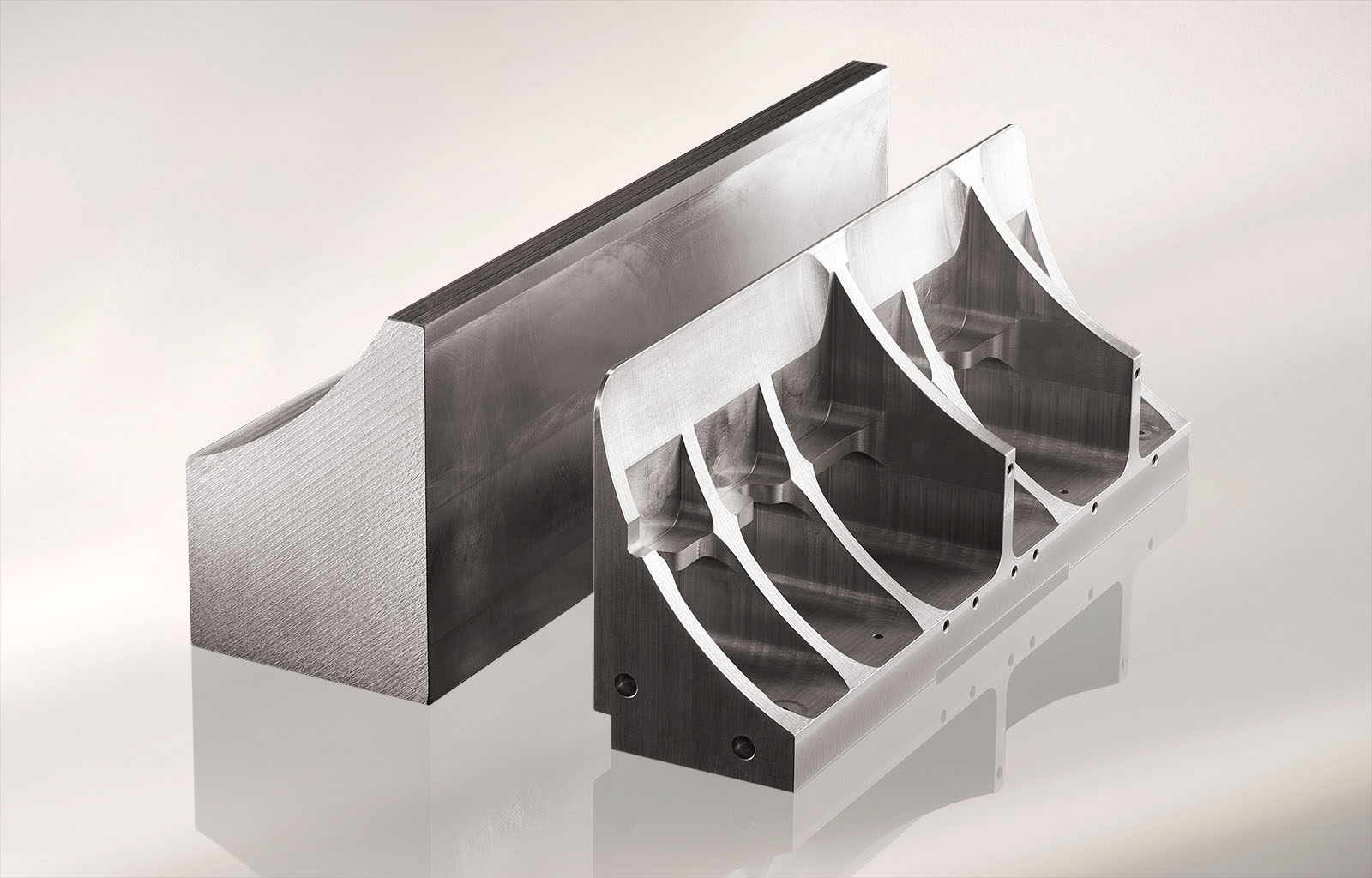

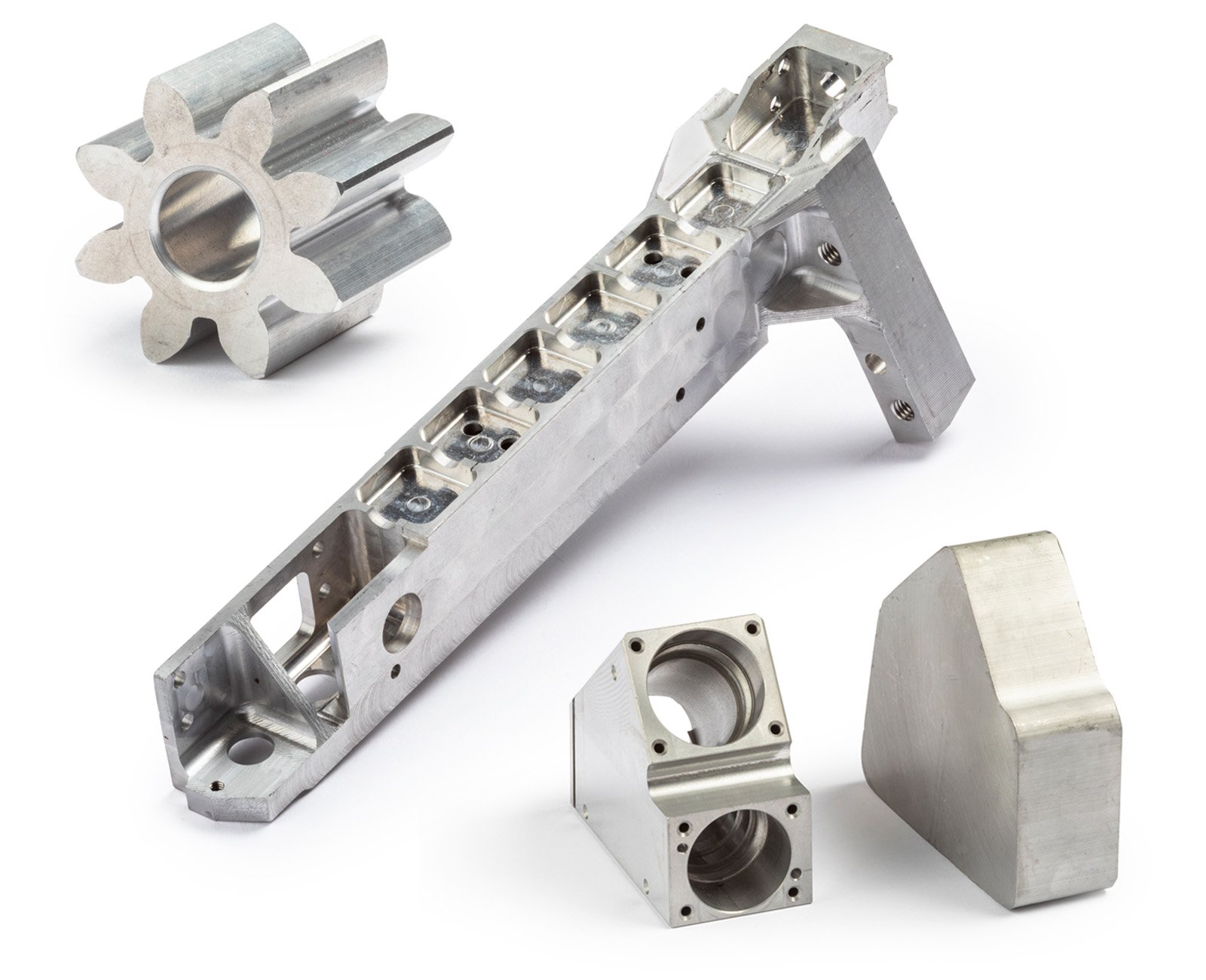

+ ...good machinability

Applications and industries

Linear technology

High precision at high acceleration due to:

• High stiffness and low weight

• Controlled thermal expansion

Metrology and optics

Optical components such as housings, with high accuracy:

• Controlled thermal expansion

• High thermal conductivity

Aerospace

Lightweight precision part in wide a temperature range:

• High stiffness and low weight

• High thermal conductivity

Automotive

Transmission parts with:

• High strength and low CTE

• Good machinability and wear resistance

Get in touch with us

Gränges Powder Metallurgy additive@granges.com Address Granges Powder Metallurgy SAS St Avold Nord ESPA Europort 57500 Saint Avold France |

HongKong Ying Jiang limited. ROOM 232,2/F SECURE HOUSE 68 HOW MING STREET KWUN TONG KL, HONGKONG +00852-28150191 mackli@yingjiang-hk.com Shanghai Jianghe Technology Co., Ltd. Room 302,Building 7, No.168 Jixin road, Minhang district of Shanghai +86 21 5488 2601 mackli@yingjiang-hk.com |

颖疆(香港)科技有限公司 香港观塘街何明街68号安全屋2楼232室 +00852-28150191 mackli@yingjiang-hk.com 上海疆禾科技有限公司 上海市闵行区集心路168号7号楼302室 +86 21 5488 2601 mackli@yingjiang-hk.com |

svenska

svenska

中文(中华人民共和国)

中文(中华人民共和国)

日本語

日本語