Cutting-edge atomization and

post-processing technologies

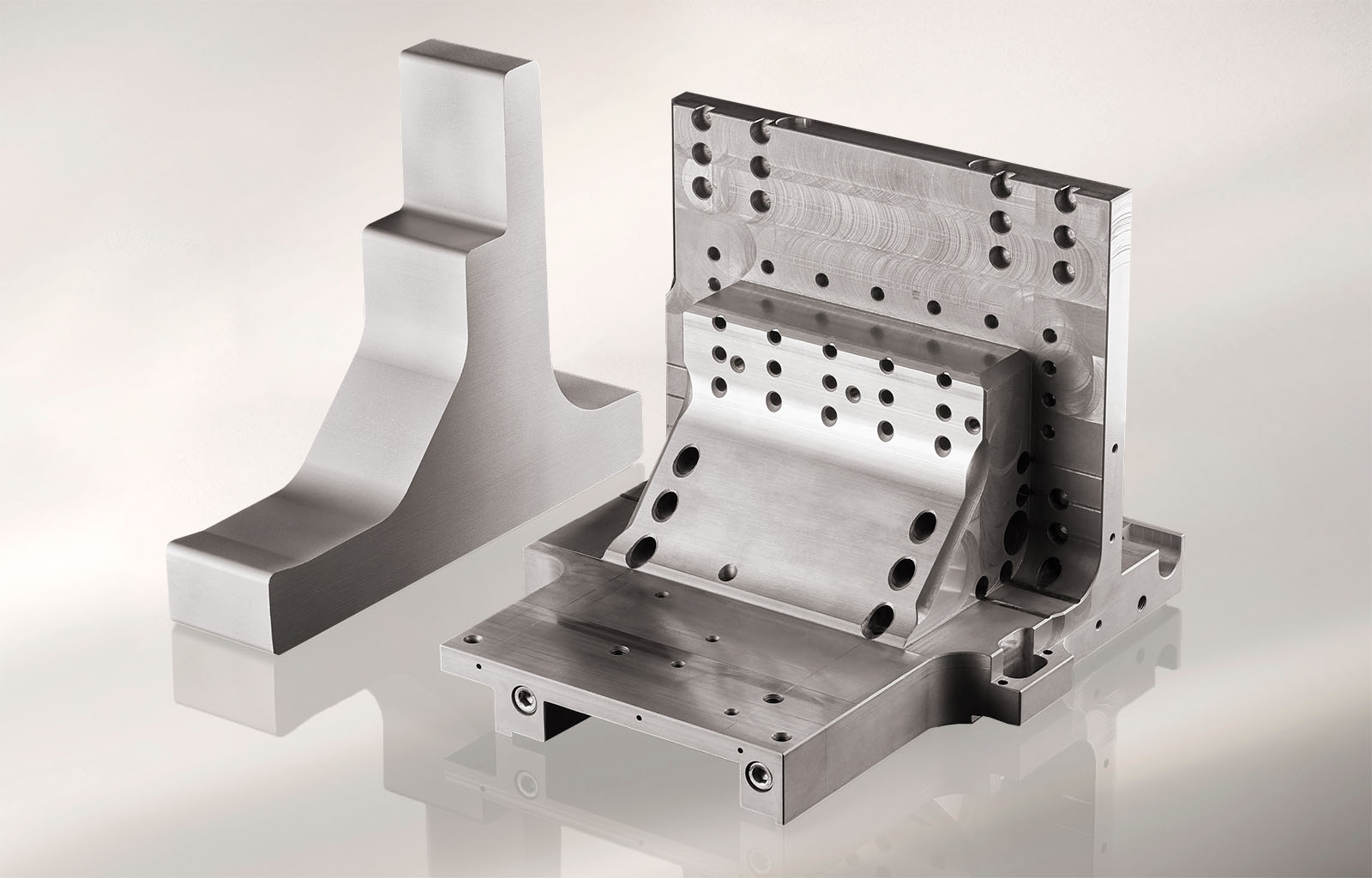

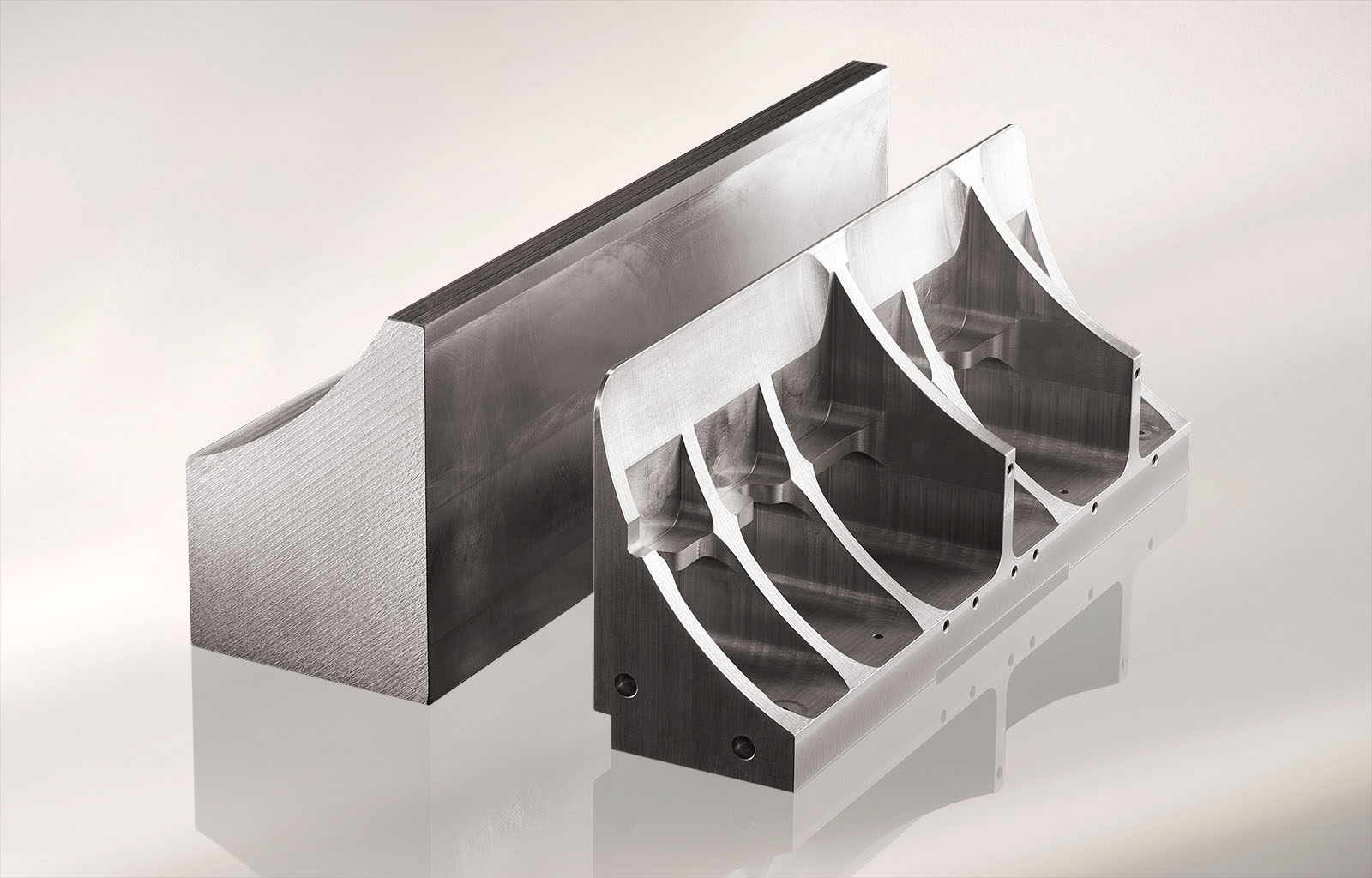

Gränges Powder Metallurgy specializes in advanced aluminium powder materials for applications like additive manufacturing and high-performance alloys. Its proprietary DISPAL® alloys combine low thermal expansion, high stiffness, and excellent durability at a fraction of steel's weight, making them ideal for industries requiring precision and reliability. With over 30 years of expertise, Gränges delivers high-quality aluminium powders using cutting-edge atomization and post-processing technologies, tailored to customer specifications. Sustainability is integral, leveraging aluminium’s recyclability and versatility for green innovation.