Very good form stability and high stiffness

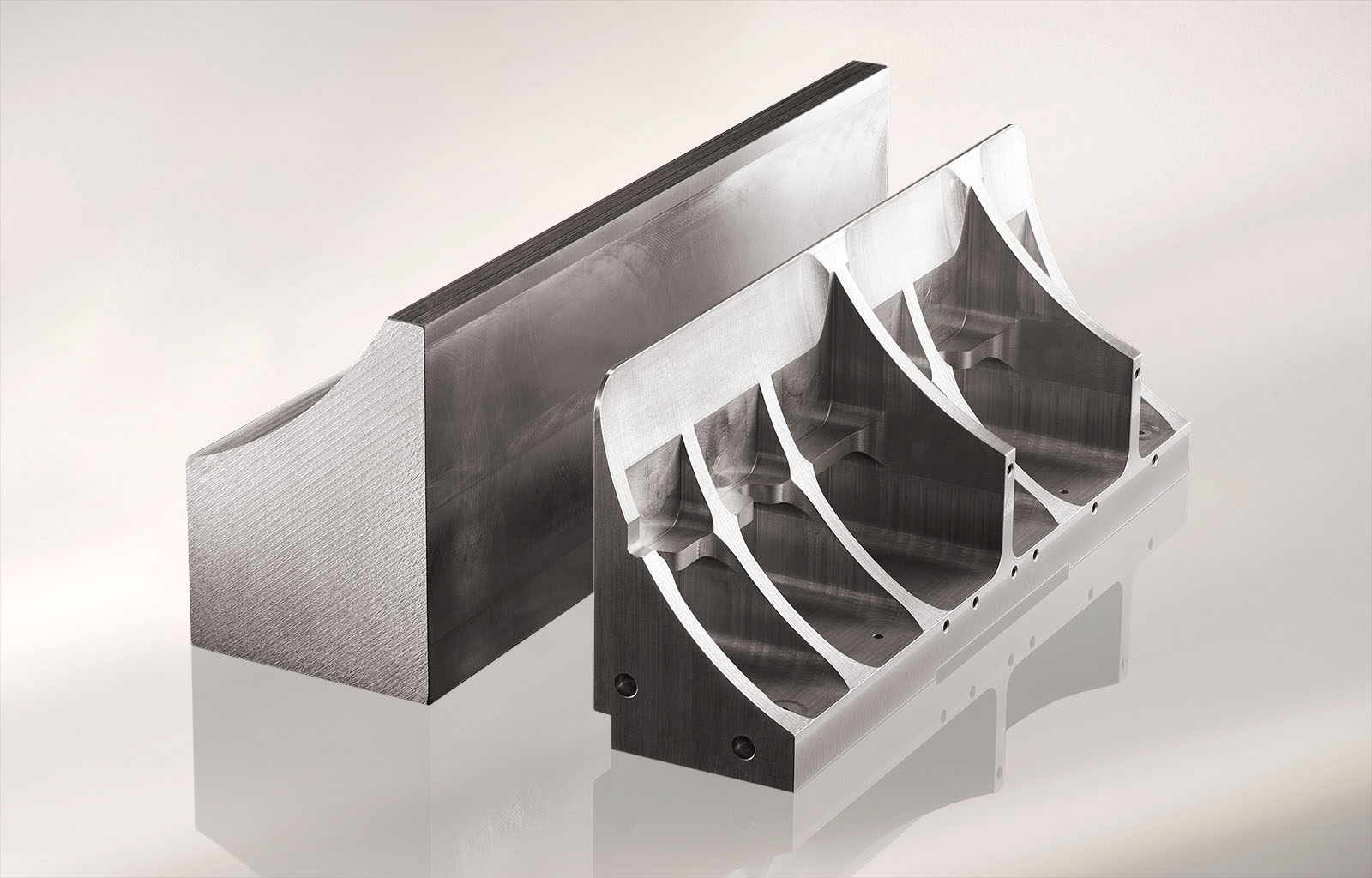

The powder metallurgical process makes the alloys solidify extremely quickly. This results in the material having an extremely fine grain and homogeneous microstructure.

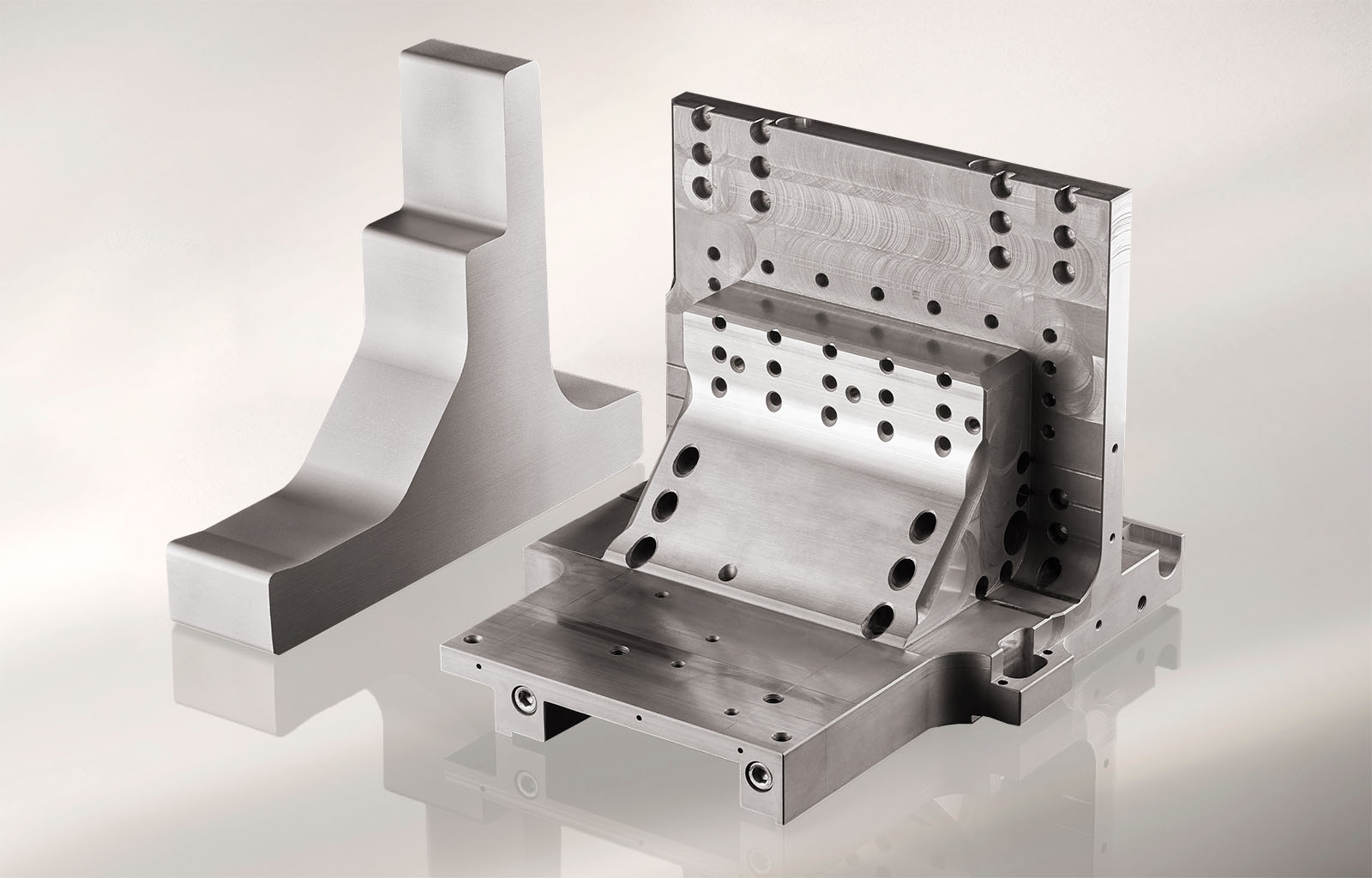

The DISPAL® material offers a higher specific stiffness than titanium alloys and steels. This combined with a high thermal conductivity and low thermal expansion gives it an exceptional form stability.

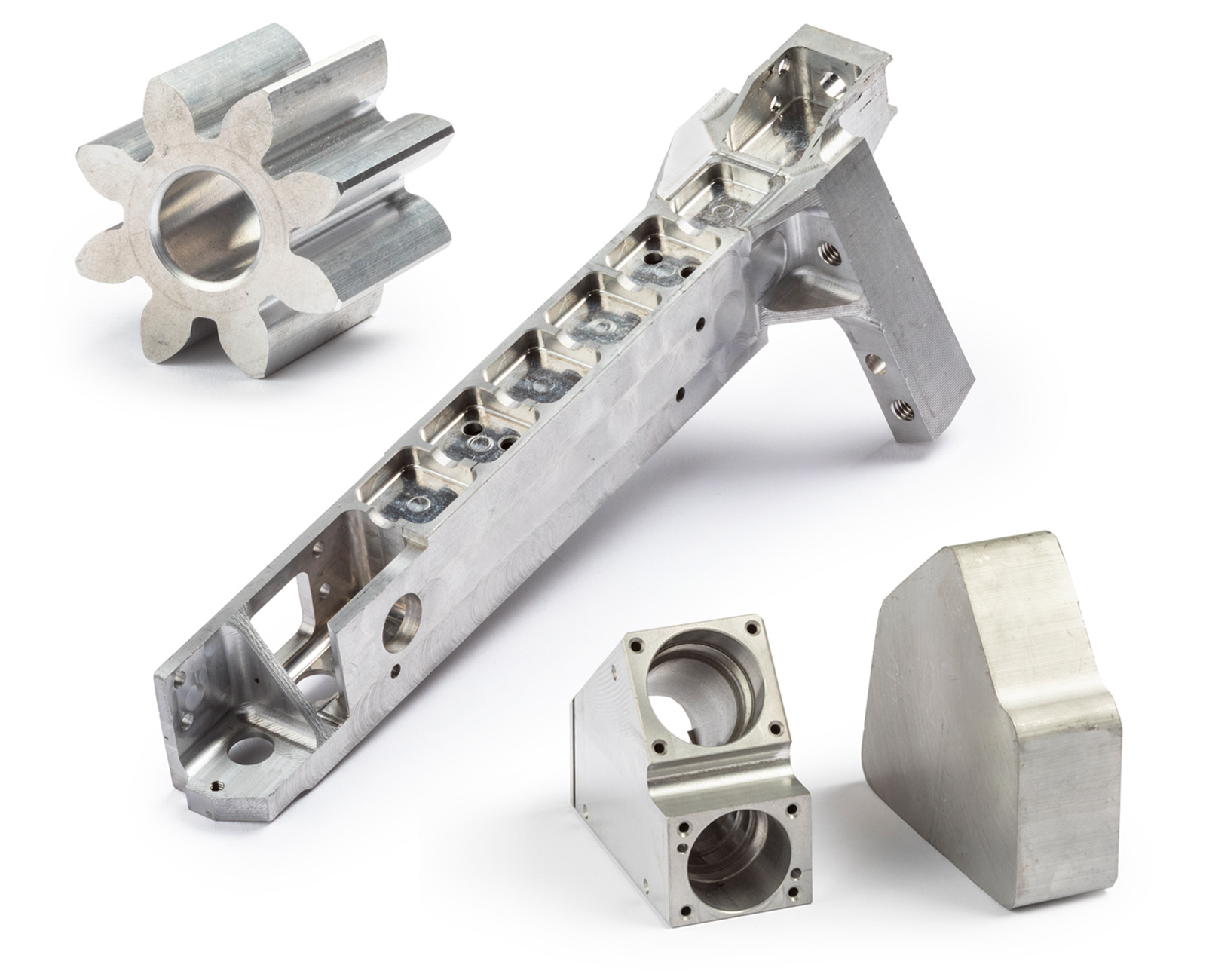

DISPAL® has properties comparable to those of steel but at only a third of its weight. It has a thermal expansion rate comparable with steel and a resistance to wear on the same level as cast iron alloys.