Sustainable supply and recycling

Gränges’ plan for sustainable supply and recycling is focused on recycling growth, green supply of metals and energy, and ensuring responsible sourcing practices. A strong focus is to invest in partnerships with customers and suppliers, in new technical solutions and remelting, as well as in increased sourcing of renewable electricity..

249 ktonnes

sourced recycled aluminium

46%

share of sourced recycled aluminium

All sites

certified against ASI's sustainability standards

100%

Supplier Code of Conduct commitment

Gränges’ 2030 goal is to reach 500 ktonnes of recycled volume, a tenfold increase from the 2017 baseline. In 2024, Gränges achieved a record-high recycling volume of 249 ktonnes, equivalent to a 5.3x increase from 2017.

This represented a significant step towards a more circular aluminium value chain, driven by investments in recycling capacity, strategic partnerships, and product innovation.

Gränges sources pre- and post-consumer materials from recycling companies and customers and recirculates processed aluminium from its own operations.

To further drive circularity, Gränges also focuses on alloy innovation, ensuring that both pre- and post-consumer scrap can be efficiently remelted to meet customer demands for sustainable aluminium solutions.

Gränges is accelerating decarbonization by expanding the use of both recycled and low-carbon primary aluminium. Recycling reduces the need for carbon-intensive raw materials, cutting emissions by up to 95 percent. In 2024, Gränges reached record-high recycled volumes of 249 ktonnes, a 5.3x increase from 2017, driven by strategic partnerships and investments in recycling capacity.

To further reduce Scope 3 emissions, Gränges also focuses on securing low-carbon primary aluminium through long-term supplier partnerships. In 2023, the company finalized a joint venture with Shandong Innovation Group (SIG) to secure access for its Shanghai facility. Additionally, a new agreement with Rio Tinto strengthens low-carbon sourcing in Gränges Americas. These initiatives are expected to significantly impact the company’s decarbonization performance over time.

Promoting a responsible supply chain

With a supplier base of more than 3,500 suppliers globally, Gränges has an indirect impact on both environmental and social sustainability. Gränges wors to mitigate sustainability risks and increase sustainability performance in the supply chain through supplier collaboration.

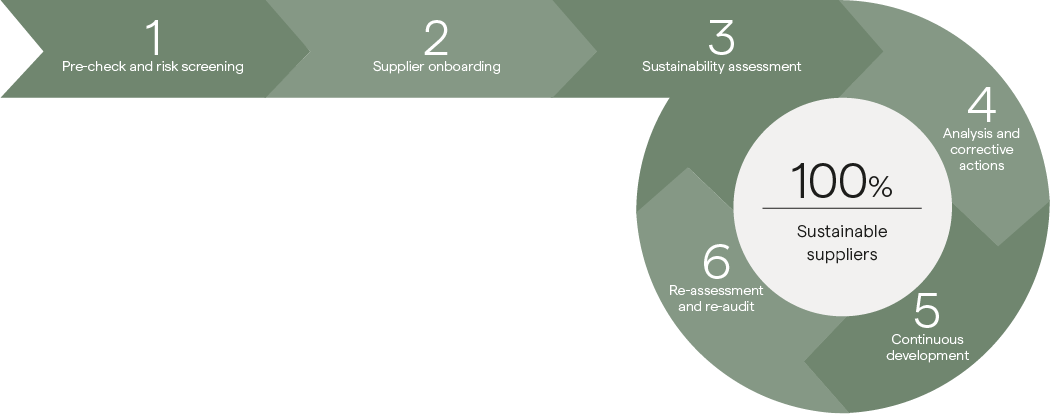

New responsible sourcing program

In 2024, Gränges finalized and initiated the roll-out of its updated responsible sourcing program. The program includes a pre-check and sustainability risk screening for all new potential suppliers, along with an extended onboarding process covering sustainability training. Supplier risk categorization is based on sustainability risks and business impact (measured as annual spend), with follow-up actions including third-party on-site audits or evidence-based desktop assessments. As part of its responsible sourcing efforts, all Gränges facilities have been certified in accordance with the ASI Performance and Chain of Custody Standard since 2023.

-

Pre-check and risk screening

Potential supplier-specific sustainability risks are identified based on environmental, social, and corruption risks associated with the supplier’s country of origin and sector. The risk scoring model used is validated by a third-party. -

Supplier onboarding

Supplier signs the company’s Supplier Code of Conduct or has an equivalent standard in place, as part of onboarding new suppliers. Sustainability trainings are conducted with high and medium risk suppliers to raise their sustainability awareness and efforts. -

Sustainability assessments

Suppliers are addressed with third-party audits or thirdparty desktop assessments to further disclose sustainability performance – depending on the suppliers’ business impact and sustainability risk. Traders will be assessed using a self-assessment questionnaire. -

Analysis and corrective actions

Suppliers are contacted to discuss findings and mitigating actions if any non-compliance against the sustainability principles stipulated in Gränges’ Supplier Code of Conduct is raised in the sustainability assessments. -

Continuous development

Sustainability performance ratings are integrated into local supplier review procedures and tools such as supplier scorecards and discussions. Trainings are provided as applicable to support suppliers and help them improve. -

Re-assessment and re-audit

Suppliers’ sustainability risks and business impacts are annually reviewed. The frequency of re-audits is at least every three years. The frequency of desktop re-assessments is based on the assessment score, but at least every three years.

svenska

svenska

中文(中华人民共和国)

中文(中华人民共和国)

日本語

日本語